Sales & Support

SALES & SERVICE

For Sales and Service of the Baier® Manway, contact:

Phone: 1-844-363-7969

Email: [email protected]

Frequently Asked Questions

What tools are necessary to open and close the Baier® Manway?

How long does it take to open and close the Baier® Manway?

Has the Baier® Manway been approved by AAR?

What kind of testing has the Baier® Manway been subjected to?

What is the material of the Baier® Manway?

What kind of gaskets work with the Baier® Manway?

How many o-ring material types are there?

How do I buy a Baier® Manway?

Troubleshooting the Baier Manway

Unable to open the manway cover? The ram will not rotate counterclockwise to release.

The ram may have been grossly over-torqued when closed. While Baier Rail cannot recommend or instruct on an exact or particular method of opening the cover when it has been over-torqued during closing, here are some common methods we have seen used by some operators to address the issue. No matter what method you choose, you must follow all safety guidelines for the Baier Manway and those in place at your facility.

To release an over-torqued manway you will need to use the same or greater amount of torque that was applied to close to open the manway cover. Common methods are using wrenches with extra-long handles, come-along ratchets or pneumatic air tools. Always discuss any method you want to use with your facility manager prior to attempting to open an over-torqued cover.

To prevent this issue from reoccurring and causing delays in the future, communicate your issues to your supervisors and create a preventative action plan. As well, file corrective action procedures with your partner facilities to prevent over-torquing of the cover at the time of loading or closing.

The Manway is clearly marked with instructions that state that the ram should not be torqued to over 200 ft/lbs. [Insert photo of cover sticker]

For more information on over-torqued rams please review our video: Baier Manway – How a Single Bolt Can Work with Less Torque. This is a detailed video about how the o-ring seal is engaged and how to properly tighten the ram and set to torque to between 100-200 ft/lbs. All operators, installers and mechanics of the Baier Manway should watch this video.

Unable to open the manway cover? The cover is loose and vented but I cannot get the cover to flip open

It may be that the strongback needs to rotate counterclockwise into the open position. To rotate the strongback, pull the locking pin while simultaneously rotating the strongback counterclockwise by pulling on the loop handle.

Once in the open position, look for the release catch to make sure it is disengaged at the same time you are trying to lift-up on the cover.

The cover has a lift assist spring to lighten the weight of the cover. When released the cover should “float” just above the closed position.

Unable to rotate the Strongback? The ram has been fully released but the strong back is stuck in place.

The locking pin prevents the strongback from rotating counterclockwise to the open position. If the locking pin is released and the strongback still will not move, the problem may be that the strongback jacking feature is still in contact with the nozzle flange. To release this, rotate the ram a ¼ turn counterclockwise. With the locking pin released the strongback should rotate freely.

How do I replace the o-ring?

Use a soft plastic tool whenever possible to remove the o-ring. If using a metal tool make sure the leading edge is rounded, as in the case of a bicycle or motorcycle tire iron, and preferably made from aluminum, not steel. Never use a metal tool that can scratch the metal surface.

Insert the tool into the groove on the cover and pry the o-ring out around the circumference.

Use only a new o-ring seal manufactured by Baier Rail – Part number 08867-705A. Always check the condition of a new o-ring to ensure there are no cracks or scrapes. Run your fingers around the o-ring to feel for any defects.

With the cover fully open, insert the o-ring into the groove, starting at the bottom and moving both hands around and up to force the o-ring to roll into the groove all the way around the cover. The o-ring will snap into place and should be fully secure. Don’t worry about slightly stretching the o-ring. It was designed to do so.

The locking cap assembly will not close. I cannot get the holes to line up so the pin can be inserted. What do I do?

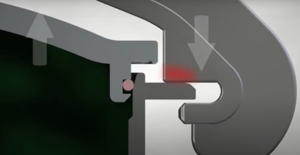

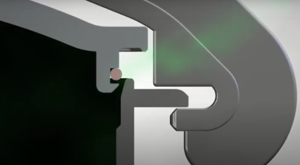

T his situation is typically due to the cover not being closed all the way. The cover needs about 5 ½ turns on the ram to be completely closed. Closure is evident with the cover and upper rim of the nozzle making metal to metal contact as illustrated at the red arrow in the picture below.

his situation is typically due to the cover not being closed all the way. The cover needs about 5 ½ turns on the ram to be completely closed. Closure is evident with the cover and upper rim of the nozzle making metal to metal contact as illustrated at the red arrow in the picture below.

Please see the section of the video: Baier Manway – – How a Single Bolt Can Work With Less Torque starting at 6:34

The cover is crooked and not level.

In rare cases, it is possible, but unlikely, that someone could torque the cover down crooked, as the system is designed to be self-aligning. If this happens the cause could be an obstruction, like the commodity attaching to the sealing surface, or grime / debris build-up over time and not being cleaned off. The fix for this situation is to open the cover, inspect and thoroughly clean the o-ring and nozzle sealing surface, then close the cover again