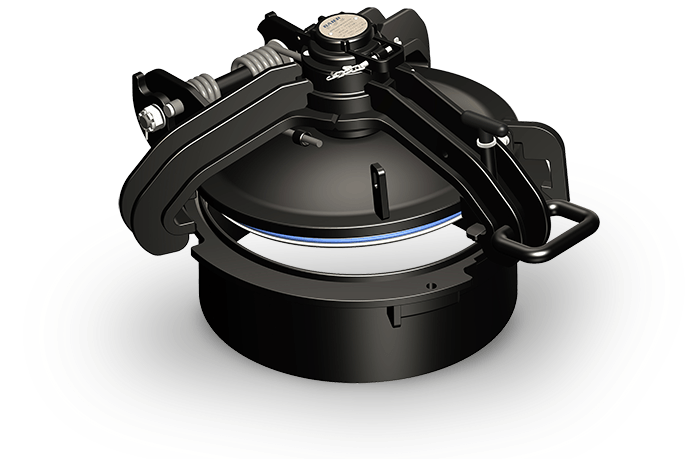

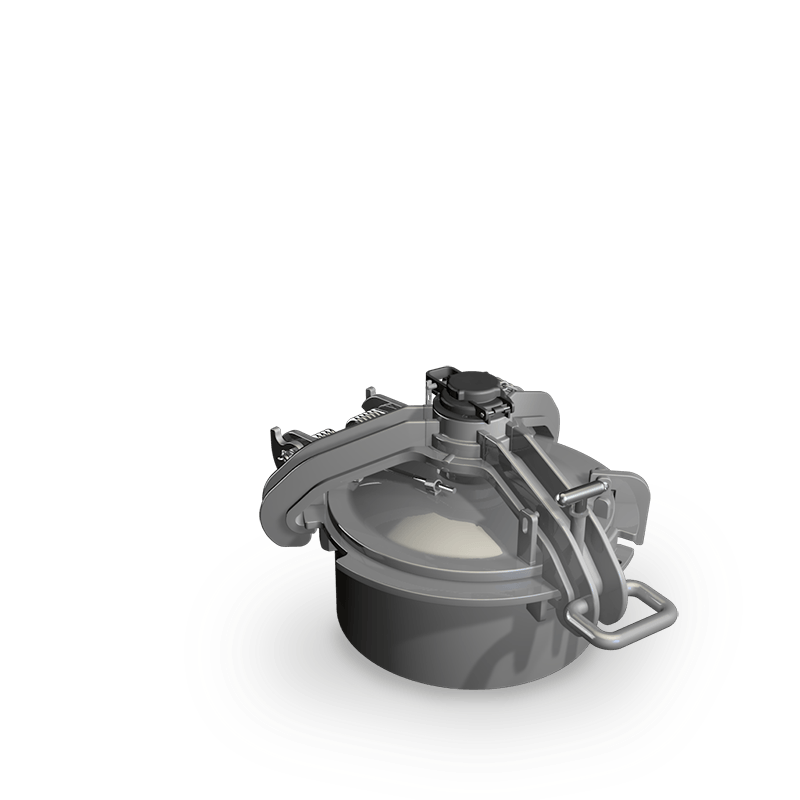

The Baier® Manway

The patented Baier® Single-Bolt Manway is an innovative and proven solution for the railway tank car industry. A completely reinvented manway, purpose-built for DOT-111 and DOT-117 tank car applications and compatible with most commodities transported in non-pressure general purpose service cars. Baier’s patented O-ring sealing system, replaces the traditional flat gasket, creating a superior seal with ease-of-use and cost-saving features.

The Baier manway is designed to open and close more quickly and safely than alternative manway products, greatly reduce potential non-accidental releases (NAR’s) and reduce or eliminate many other common tank car manway problems. It is efficient, strong, durable, and cost-effective.

The Baier Single-Bolt Manway is approved by the AAR (American Associate of Railroads).

The Baier® Single-Bolt Manway Cover Assembly has been designed to eliminate common Tank Car manway problems. It is quick, strong, durable and cost-effective.

Sold by:

Feature Highlights

- AAR Approved Design – E152106

- Single-Bolt Engagement

- O-Ring Sealing System

- Retrofit or New Construction Models

- Integrated lift-assist spring allows for easy opening and closing of the cover

The Baier® Single-Bolt Manway

The Baier Single-Bolt Manway is a unique solution for sealing the tank car manway. This patented system is fundamentally different from all other traditional manway designs. This new approach to sealing employs a single-bolt ram and strongback arm to close the cover and create a superior seal using O-ring technology. Baier’s design replaces the traditional compression seal of flat gaskets used in traditional multi-bolt covers. Instead, it uses the power of its single-bolt design to close the Baier Manway cover easily and quickly; the cover employs a Teflon® encapsulated O-ring to create a superior seal against the surface of the interior of the nozzle.

Unlike flat gaskets, the O-ring cannot be crushed through the process of tightening the cover with the single-bolt. Turning the single-bolt drives the cover and O-ring in place within the nozzle. Further turning beyond its natural stopping point does not place any additional pressure on the O-ring or increase the seal strength. The natural resiliency of the O-ring, laterally engaging with the inside surface of the nozzle achieves an effective and consistent seal.

Due to the single-bolt design, there are no:

- Eyebolts, and thus no damaged eyebolts

- Time-consuming, multi-bolt torquing procedures

- Crushed flat gaskets

- Unequal loading that may occur when closing a multi-bolt cover

The operator can create a more consistent seal in a quick and efficient operation with simple hand tools. No retorqueing is needed and no special tools are required.

The Baier® O-Ring Sealing System

The secret to the success of the Baier® manway lies in our patented use of O-rings to achieve a superior seal. Instead of compressing a flat gasket material against a sealing lip to achieve a seal, the Baier Manway uses an O-ring positioned between the nozzle wall and the cover sheer ring. This creates a more consistent and uniform engagement with the nozzle, resulting in a more reliable seal. Any internal pressure only works to the advantage of the sealing system; actually, enhancing the sealing force as the O-ring reacts to the pressure.

Baier’s manway uses a special encapsulated O-ring made from Teflon® polytetrafluoroethylene. Our O-ring can withstand a large number of operational cycles and is compatible with a wide range of commodities, saving costs by reducing the number of times it needs to be replaced compared to a flat gasket and lowering the requirement to stock large quantities of different types of replacements gaskets made of various materials.

Watch The Baier Manway Video

The Baier® Single-Bolt Manway Cover Assembly has been designed to eliminate common tank car manway problems. It is quick, durable, strong and cost-effective.