The Baier Manway - Benefits, Models, and Parts

Baier® Rail designed the Single-Bolt Manway from the ground up to meet the specific demands of the Tank Car industry and address the common causes of NAR’s. Others in the industry have attempted to overcome these problems with new gasket materials and different gasket styles to work with the traditional multi-bolt manway. Baier Rail reimagined the manway concept. During more than two years of development Baier worked with criteria provided by customers working in the rail tank car industry, designing, testing, and perfecting a purpose-built manway cover assembly. The resulting product is nothing short of game-changing – a design so revolutionary we patented its unique features: a system with superior sealing, ease of use, safety and cost savings!

The Benefits of the Baier Manway

The Baier® Single‐Bolt Manway system design promotes environmental and operator safety. Traditional eye-bolt designs can have serious shortcomings which may represent trip-hazards, excessive time loading and unloading on top of the tank car, and other operational dangers. Baier’s manway is a much safer design.

A review of the Baier® Single-Bolt Manway features:

- Reduced Maintenance. A single robust threaded central ram bolt, inside of a grease containment chamber, protected from the elements by seals can be serviced by a standard grease lubrication fitting. This replaces six or eight threaded, exposed, and unlubricated eyebolts prone to rust and debris from the environment. Maintaining the grease lubrication over a long period of time is inherent in the system, eliminating the maintenance process of checking and replacing damaged or worn eyebolts, nuts, washers, and button head rods that exist on standard multi-bolt manways.

- Designed to Reduce Gasket Replacement Costs and NAR’s. A standard Teflon® encapsulated O‐ring works for almost most commodities and lasts for repeated filling cycles. Use of an O-ring eliminates flat gaskets which are commonly required to be replaced after each cycle or load. Since the O‐ring is never mechanically pinched like a flat gasket there is a much lower risk of damage with proper use. General abrasion and wear allow the O-ring to be used repeatedly. Flat gaskets are often torn or pinched due to uneven torquing or over-torquing of the multi-bolts in response to leaks. Increasing torque applied to the Baier manway does not increase pressure on the O-ring. Always clean the sealing surface on the nozzle and check O-ring for damage when trying to resolve sealing issues.

- Easy to Tell When Its Closed; Vibration Won’t Loosen the Cover. Visible positive close indicator. – If the cap assembly is down and the seal ping is inserted, the cover is fully closed and can’t open on its own. Rail vibration will not loosen the single-bolt, cover, or break the seal due to cap’s design. On traditional multi-bolt models, it is easy to mistakenly leave the eyebolts untightened without noticing. With the Baier® Single-Bolt Manway, it is obvious when the unit is fully closed. Our manway unit has a special top cap assembly with a closure pin; if the pin is in place while the cap is closed, you are sure it is locked and fully closed; no guesswork here. This is because in order for the top cap cover to close and secured with the locking pin in place, the holes for the locking pin must be aligned, the main cover MUST be fully tightened for this to happen. If this is not the case, the cap will not close, and the operator cannot insert the pin. This “not-locked status” is visibly obvious to the loader and can be seen from a distance. Cap down and pin inserted = fully closed and locked!

- Secure Cargo. Cargo seal tag can be affixed to this single secure locking point to ensure security of the cargo. The Cover cannot be opened without releasing the cap.

Teflon® is a registered trademark of THE CHEMOURS COMPANY FC.

A Modern Solution – The Baier Manway

A review of the Baier® Single-Bolt Manway operator safety features:

- The encapsulated O‐ring is positioned between the nozzle wall and the cover sheer ring. This design creates consistent and uniform compression without the inherently problematic process of compressing a flat gasket in a multi‐bolt manway.

- Controlled Venting. The venting process allows the operator to gradually adjust the flows of vapors past the cover and seal while maintaining a protected and controlled release. The Baier Manway’s cover assembly includes a robust Strongback arm that serves both as the primary restriction from an uncontrolled opening and also as a means to lift the cover when under vacuum. A secondary safety catch must be released after the primary strongback is moved to the open position in order to fully open the cover.

- Safety Latch Provides for A Safer, More Controlled Opening Process. The Baier® Single-Bolt Manway has a special, gravity-controlled safety latch which prevents the cover from being lifted more than a few inches. At that point, the gravity-controlled safety latch holding the cover must be disengaged for the cover to swing open any farther. This allows for a more controlled venting and opening process.

- Spring Assisted Cover Makes It Safer and Easier to Control Opening the Unit. Only about 45 pounds of lifting force is needed to lift the cover of the Baier® Single-Bolt Manway into a fully opened position. Once open, the cover stays open using its over-center action.

- Lift Assisted Opening Helps Prevent Stuck Covers. The same single-bolt mechanism that drives the cover and O-ring into the nozzle to a closed position is used during the opening process to open and lift the cover away from the nozzle. The robust single-bolt ram can be used to release most stubborn materials and overcome most strong vacuum pressures. These features allow opening to occur in a safe and controlled manner.

- O-Rings Designed Not to Fall Into The Tank. Since the O-ring is larger than the nozzle opening in the Baier® Single-Bolt Manway, it is very unlikely the O-ring will inadvertently fall into tank where it would need to be retrieved. Flat gaskets employed on standard multi-bolt manways are more at risk of falling into a tank car opening.

Safety is our Top Priority - The Baier Manway

A review of the Baier® Single-Bolt Manway safety features:

- Operators Will Spend Less Time Exposed on Top of the Tank Car. The single-bolt design allows the operator to open or close the Baier Manway in about a minute and requires no re-torquing. This is all possible because the elimination of eyebolts. Because there are no eyebolts on the Baier Manway, this eliminates the requirement of an operator to torque 6 – 8 bolts, then repeat this process up to 3 additional times, following complex written procedures created to address ongoing problems with flat gaskets.

- Easy to See Positive Close Indicator. On the traditional eye-bolt model, it is easy to mistakenly leave the eye-bolts untightened without noticing. With the Baier® Single-Bolt Manway, it is obvious when the unit is not fully tightened down. Our manway unit has a top cap cover that is very easy to see when it is left open. In order for the top cap cover to be closed and cinched with the locking pin, the main cover MUST be fully tightened, otherwise the cap will not close, and the operator cannot insert the tamper tag. This “not-locked status” is obvious to the loader, and can be seen from a distance. Cap down = locked!

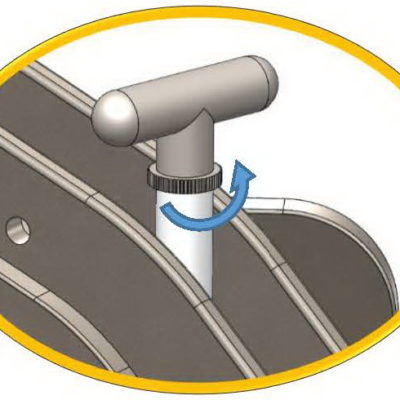

- Vibration Won’t Loosen Eye Bolts. Vibrations will not loosen the cover. Eyebolts on traditional style manway covers can loosen over time through vibration. With the Baier’s single-bolt design, this is not possible. This is achieved through our unique system design. Baier’s Manway uses a single, powerful 3-inch ram bolt with thread geometry that inherently resistant to back-driving and loosening. Our system also incorporates a top cap assembly, that when closed, provides a positive lock for the ram. Once the cap is down and the locking pin is installed, the ram bolt cannot turn and thus cannot loosen.

- O-Ring Design Minimizes or Eliminates Cargo Leakage and Non-Accidental Releases (NARs). The Baier® Single-Bolt Manway system is designed with an O-ring, instead of a flat gasket, to minimize or eliminate cargo leaks and NARs.

- Controlled Venting. The venting process allows the operator to gradually adjust the flows of vapors past the cover and seal while maintaining a protected and controlled release. The Baier Manway’s cover assembly includes a robust strongback arm that serves both as the primary restriction from an uncontrolled opening and also as a means to lift the cover when under vacuum. A secondary safety catch must be released after the primary strongback is moved to the open position in order to fully open the cover.

- Safety Latch Provides for A Safer, More Controlled Opening Process. Once the positioning pin of the Baier® Single-Bolt Manway is pulled up and the strongback is swung into the OPEN position, the cover can be lifted, but only for a few inches. At that point, a gravity-controlled safety latch holds the cover and must be disengaged for the cover to swing open any farther.

- Spring Assisted Cover Makes It Safer and Easier to Control Opening the Unit. Only 45 pounds of lifting force is needed to lift the cover of the Baier® Single-Bolt Manway into a fully opened position. Once open, the cover stays open using its over-center action.

- Less Need for Pry-Bar to Open Stuck Covers. In this first stage of opening, the jacking of the cover should, in most cases, break the cover loose from any sticky or hardened cargo and release any residual pressure. As a result, the operator need not use pry-bar in most circumstances.

Reducing Non-Accidental Releases – The Baier Manway

Our research of traditional manway designs revealed some fundamental design shortcomings in multi-bolt manways that use eyebolts to create a seal, including, permanent deformation of sealing gaskets; stretched eye-bolts due to over-torquing and metal fatigue; “scalloped” stress of the cover resulting in unequal sealing, and broken “ears” on the cover, to name a few. We also found that, at a certain pressure, covers based on earlier designs may lift, resulting in releases. These earlier designs were not meant to handle the demands of today’s tank cars high internal pressures or the very high torque capacity of modern pneumatic tools.

Baier® Rail designed the single‐bolt manway from the ground up to meet the specific demands of the tank car industry and address the common causes of NAR’s. Others in the industry have attempted to overcome these problems with new gasket materials and different gasket styles to work with the traditional multi-bolt manway, instead, Baier Rail reimagined the manway concept and developed a modern solution designed to increase efficiency, decrease overall costs, and most importantly, reduce NAR’s, all while maintaining the highest production quality and meeting the rigorous regulatory standards of the AAR.

- Teflon Encapsulated O-Ring Design. By replacing flat gaskets with our patented sealing system that uses an O-ring contained on the cover which seals against the interior wall of the nozzle, Baier created a system which has much less wear and tear on the sealing O-ring as compared to flat gaskets. The risk of gasket deformation or breaking has been greatly reduced. The natural resiliency of the O-ring seals against the nozzle and creates an extremely effective seal. Multiple cycles can be achieved with a single sealing O-ring. Further, since there are no eyebolts, or multiple engagement points on the covers or “ears”, problems from breakage, wear or replacements of those parts have been eliminated.

- Increased Internal Pressure Actually Works to INCREASE O-Ring Sealing Efficiency. When pressure within the tank car increases, the pressure presses against the O-ring; the O-ring changes shape and creates even more sealing surface. Other designs rely on squeezing or crushing a flat gasket, any increased internal pressure will result in decreased sealing efficiency of a flat gasket.

- Stripped, Deformed and Elongated Eyebolts Are a Thing of the Past. The Baier Manway’s 3-inch, single ram bolt is internally contained within a sealed lubricated chamber and highly resistant to stripping, deformation binding, or corrosion. It is this 3- inch bolt that serves to drive the cover and O-ring into the nozzle when closing. It also serves as a strong mechanism to open the cover in a controlled fashion, even while under vacuum, by mechanically lifting the cover against the nozzle using the full force of the ram bolt’s threads.

Operation – The Baier Manway

The Baier® Single-Bolt Manway is designed for easier operation as compared to other manway designs:

- Operating Efficiency

- Saves time in open/close operations. About one minute per cycle.

- No re-torquing or advanced procedures

- Can operate with standard hand tools; no special sockets

- No crushed flat gaskets replaced on each load

- No troublesome eye-bolts

- O-rings last longer than flat gaskets and saves time and money

- Other Benefits

- Operates using one central ram bolt instead of 6 or 8 individual eyebolts; the single-bolt is protected in a sealed lubricated chamber.

- The Single-bolt ram mechanically releases stubborn materials and overcomes strong vacuum pressure

- Controlled venting is easy to achieve

- Positive lock-down indicator built into cap design, so time spent re-checking is minimized

Versatile O-Ring Sealing – The Biaer Manway

The secret to the success of the Baier® manway lies in our patented use of O-rings to achieve a superior seal. Instead of compressing a flat gasket material against a sealing lip to achieve a seal, the Baier Manway uses an O-ring positioned between the nozzle wall and the cover sheer ring. This creates a more consistent and uniform engagement with the nozzle, resulting in a more reliable seal. Any internal pressure only works to the advantage of the sealing system; actually, enhancing the sealing force as the O-ring reacts to the pressure.

Baier’s manway uses a special encapsulated O-ring made from Teflon® polytetrafluoroethylene. Our O-ring can withstand a large number of operational cycles and is compatible with a wide range of commodities, saving costs by reducing the number of times it needs to be replaced compared to a flat gasket and lowering the requirement to stock large quantities of different types of replacements gaskets made of various materials.

The Baier® Single-Bolt Manway is designed around a patented O-ring sealing system.

- O-ring sealing system

- Our standard Teflon®-encapsulated O-ring works with many commodities

- O-ring lasts for many more cycles than flat gaskets

- Moderate cost per O-ring

- Simple hand replacement of O-ring when needed

- O-ring is larger than the manway opening, so it is unlikely to inadvertently fall into the tank

- Designed to reduce NAR’s, avoid fines and charges

- Designed to reduce logistical interruptions

Teflon® is a registered trademark of THE CHEMOURS COMPANY FC..

Maintenance – The Baier Manway

The Baier® Single-Bolt Manway is designed for lower maintenance as compared to earlier designs:

- Maintenance Benefits:

- Eliminates need to check and replace stretched or broken bolts

- Sealed ram bolt has an extended lubrication interval

- Other required regular maintenance is limited

- Reduced gasket replacements; O-rings last longer than most flat gaskets and saves time and money

- Stripped, Deformed and Elongated Eye-Bolts Are a Thing of the Past. The New Manway’s massive 3 inch, single ram bolt is highly resistant to stripping, deformation or binding. The sealing force of the cover is designed to remain uniform.

Tested and Proven In The Field - The Baier Manway

The Baier® Single-Bolt Manway has been in use on tank cars since 2017. The service trial was completed and approved by the AAR on 10/23/2019 (AAR ST-462). Our AAR approved design (E152106) has completed rigorous in-house and real-world testing to ensure it performs well in extreme conditions. The system meets or exceeds all AAR performance criteria for manways. We’re confident you’ll be impressed by the robustness of this system.

During the products development we worked with major industry players to put it through exhaustive testing subjecting the product to extremes beyond that of the expected real-world application, to ensure it performs as designed. Below are just a few conditions that we have tested:

- Pressure

- We’ve pressurized the Baier® Single-Bolt Manway well beyond the required 207 psi for over 10 minutes, with no leaks. O-rings have been cycled dozens of times through the opening/closing operation in this same test with no decrease in performance!

- Shock and Vibration

- We’ve subjected the Baier® Single-Bolt Manway to shock and vibration testing per IEC 61373:1999 for rolling stock railway applications and it easily passed the tests.

- Thermal Cycling

- We’ve pressurized the Baier® Single-Bolt Manway to transport loads and subjected it to thermal cycling to simulate the hottest and coldest of days. We tested it for weeks. Result: no leaks.

- Versatile O-Ring

- Our standard Teflon-encapsulated O-ring works for most commodities

- O-ring lasts for many more cycles than flat gaskets

- Moderate cost per O-ring

- Simple hand replacement of O-ring when needed

- O-ring is larger than the manway opening, so it is unlikely to inadvertently fall into the tank

- Designed to reduce NAR’s, avoid fines and charges

- Designed to reduce logistical interruptions

Teflon® is a registered trademark of THE CHEMOURS COMPANY FC.